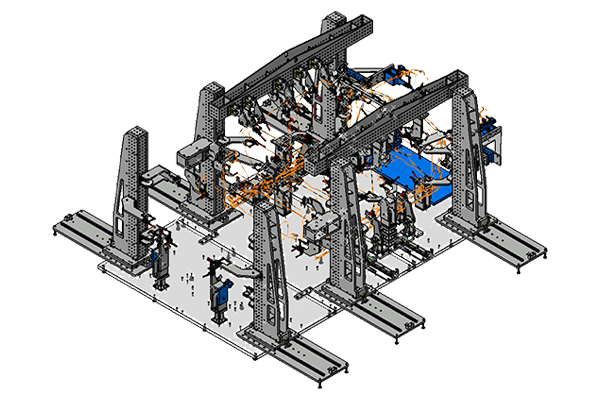

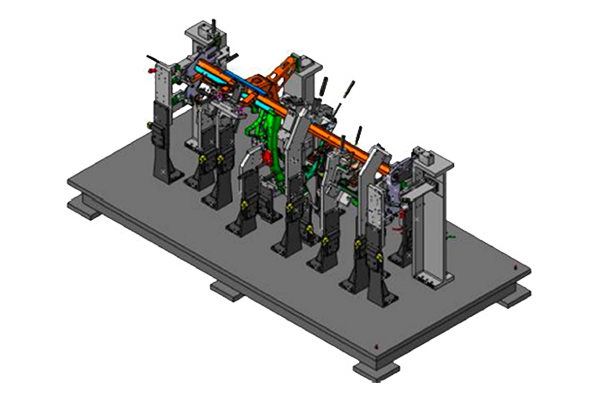

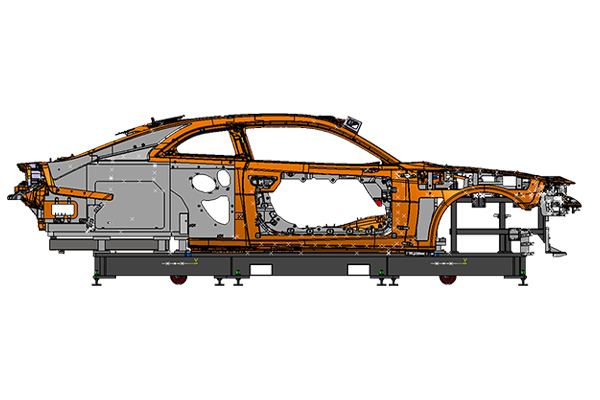

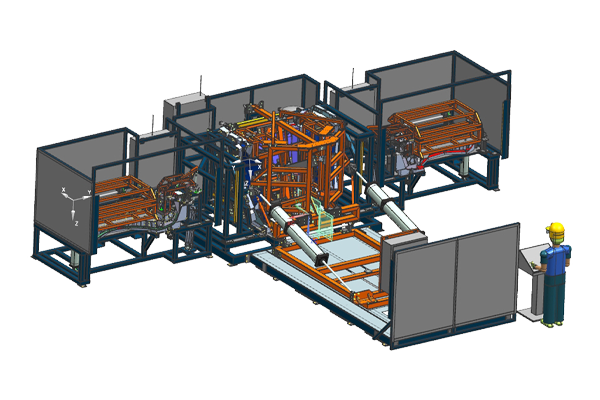

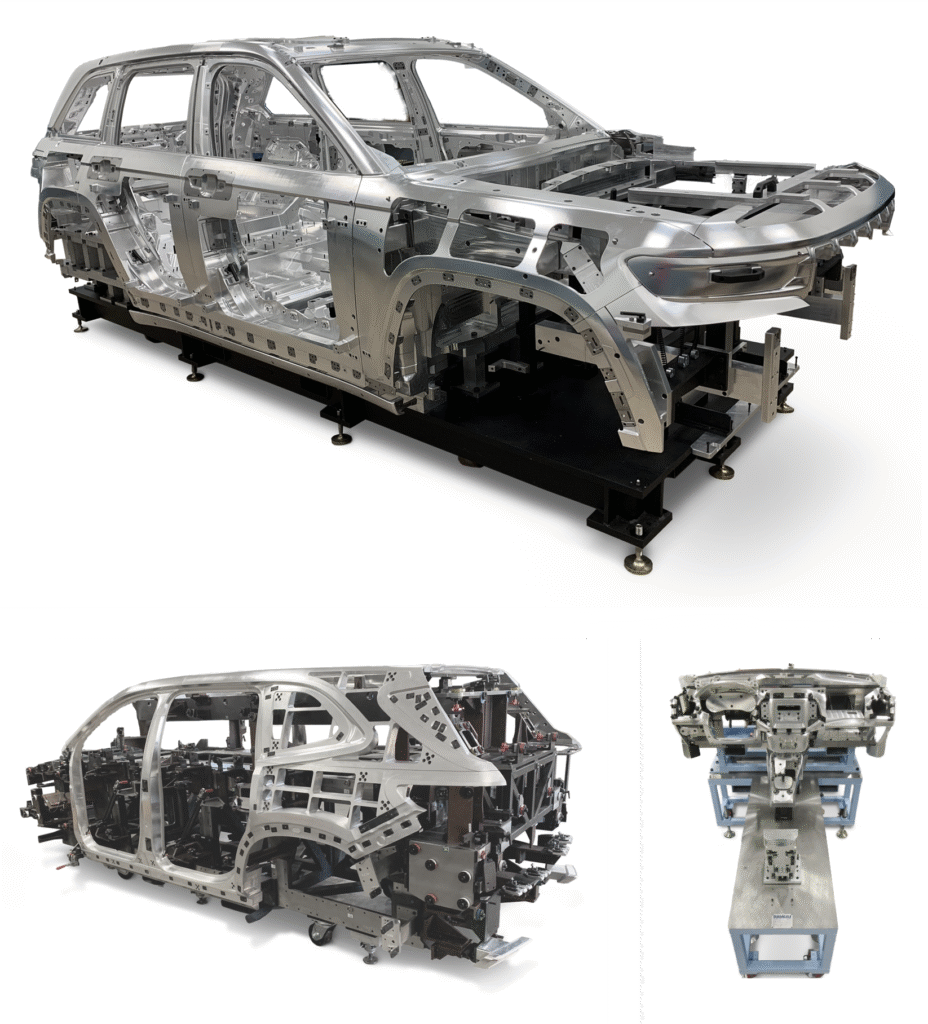

Quality Assurance Fixtures

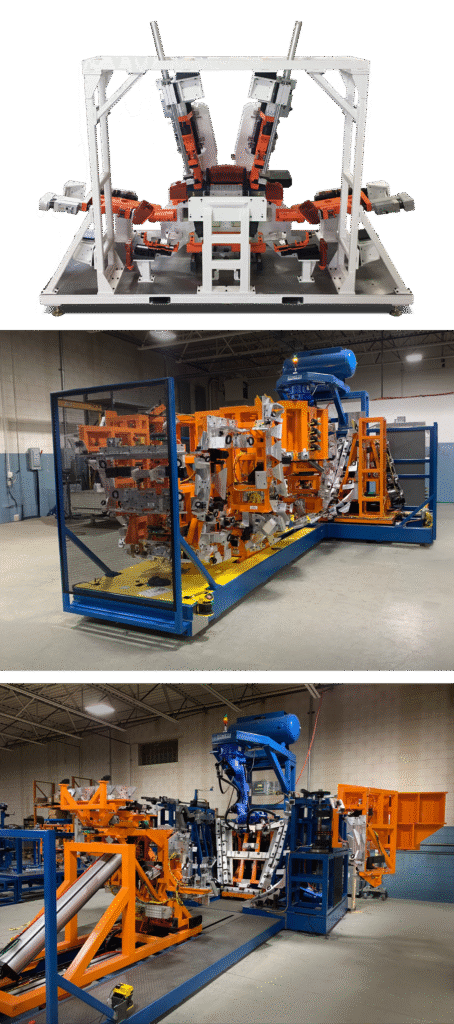

& E/I-TAC’s

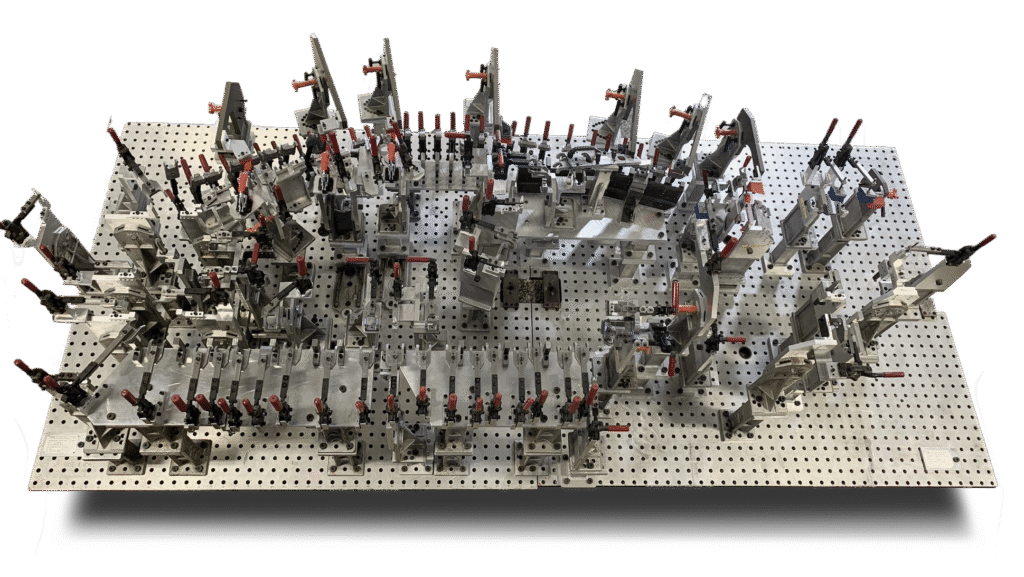

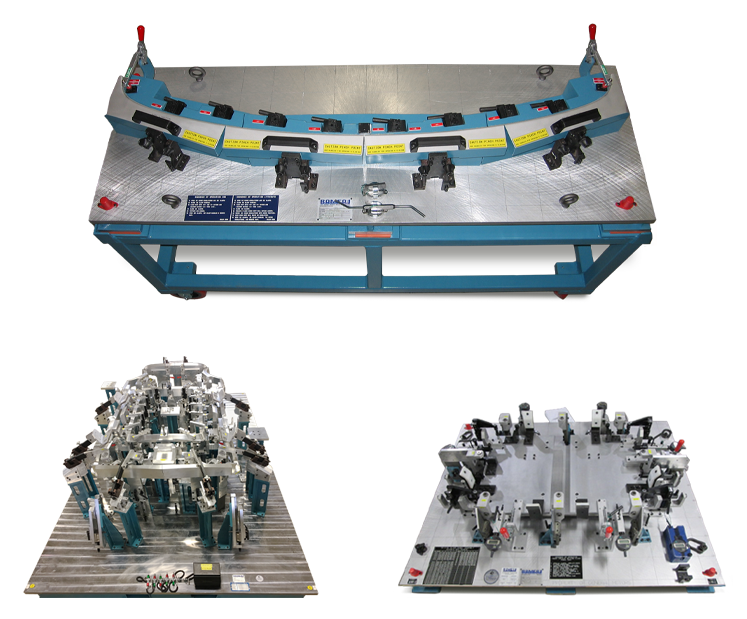

Quality Assurance (QA) Fixtures are precision-engineered tools used in the automotive sector to verify the dimensional accuracy, fit, function, and assembly integrity of vehicle components and systems. These fixtures are essential for ensuring that parts—ranging from individual panels and brackets to full sub-assemblies—meet strict engineering specifications and industry standards before advancing in the production process or reaching the customer.

By deploying QA fixtures on the production floor or in metrology labs, automotive manufacturers can quickly identify deviations, ensure critical tolerances are maintained, and support traceability and documentation for quality audits. This not only enhances vehicle safety and performance but also reduces rework, scrap, and warranty claims—contributing to operational efficiency and brand reputation.

Romeo Technologies has been a leading provider in the development of Quality Assurance Fixtures and I/ETACs, serving a diverse range of customers across various industries.